Application of systems thinking in human resources: The next day, we had the chance to sit down with Doug Hall – speaker, writer, inventor, whiskey maker and Eureka owner! In the pasture of cattle breeding. Doug also had a prominent influence on our President Tony Rogers in creative mechanisms.

Doug talks about using a systems approach to innovation to change your company when compatibility is paramount.

Should we say, at the time of the global epidemic?

It is through this approach that Doug believes that engineers are uniquely equipped with systems thinking to powerfully change your business.

Doug Hall: I am a chemical engineer, but I have been an entrepreneur since I was 10 years old. It started about 40 years ago.

I worked at Procter & Gamble for 10 years, and then 40 years ago I started a business called Eureka! Ranch, where we help people use systems to help employees think smarter, faster and more creatively.

We also invent.

I had this invention that got out of control and the next thing you know, I was investing in it.

And so now I have a very good size whiskey business where we make custom bourbon.

In all these cases, I’m not interested in doing clones. I’m not interested in doing the lowest cost.

I’m interested in doing the funniest things I can do, and then I’m glad I was able to do it.

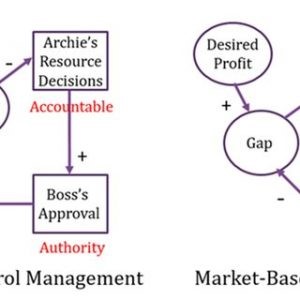

The new move we are making to make a real difference is systems thinking.

Obviously, you are very familiar with the approach that Deming took in the late 1970s and early 1980s, and he used system thinking in production.

It is a set of independent operations in a factory that work together to achieve a common goal.

This goal, of course, is to satisfy the customer and the long-term stability of the company.

Deming said systemic thinking has been applied to only about 3% of opportunities. 97 other was another opportunity in our strategy, innovation and cooperation.

So our approach is to use systems thinking to change and innovate in each person.

I think it’s less about calculations and questions that you can answer with a computer and some tables.

What we need is to look at our production system. As you can remember, hand sanitizer was a big deal.

We thought it would be nice if we could put a few bottles together and give them to them.

At first, we just made 7,000 gift bottles – well, they disappeared in 4 hours…

We heard horrible stories from hospitals, police, officers, firefighters, all without disinfectants.

Even if I were to return to “normal work”, for a few days now all I have been doing is working on hand sanitizer because we are currently asking for 1.2 million bottles of hand sanitizer.

So I went to my children and said: “Well, 1.2 million.

If we do this, we will fail. But these companies are disappointed – big and big companies!

In addition, when deliveries were reduced, they did not sit in Purell warehouses because they were accustomed to delivering it every week.

They have no warehouse, no space.

This was the result of the system.

He said: “Did you notice that I can not buy automatic equipment for it?”

I know there are limitations, boundaries, and yes, technical engineering and computing and flows, but so are human systems.

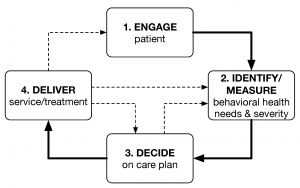

How human systems work, customer needs and what we can do for customers.

This is a different type of engineering than chemical engineering or engineering in general.

Everything stops because we want to work on one part, a silo.

We all know that systems are independent components and strive to achieve a common goal.

That is, people are in silos and do not work at all.

I thought that engineers should do the monkey work in the middle to facilitate all this.

Many engineers think like a scientist and are very cramped in their casting.

In my opinion, the reason I worked in engineering as a scientist was because I liked the interaction of those departments.

Application of systems thinking in human resources.

Engineers are uniquely equipped to understand human behavior because of what systems and what

Products, we deal with realistic results and efficient processes.

If we can apply this thinking to teams, multifaceted production processes or anything

– We have a particularly valuable opportunity to achieve better results.

For the latest news about our activities, visit our website. Artan Petro Kayhan Instagram Page.

Production of General purpose polystyrene with different grades

info@artanpetro.com

Qom Shokouhieh Industrial Town, end of the second phase, Babaei Square, Babaei St., Alam al-Huda St. 1, No. 1331

+982533346396![]()

+982533346473![]()